Since its early days, HEICO's production business has evolved into a cutting-edge producer of parts for the most demanding of industries. While firmly innovation-focused, HEICO is proud of where it came from and maintaining its family-owned roots. Jonathon Harker speaks with General Manager Jan Bernd Heimann - the fourth-generation owner of the business - and Sales Manager Tobias Grobe.

For any business celebrating a big anniversary, there's a fine balancing act to be made. You want to celebrate the past, but not at the expense of emphasising all the latest innovations and developments the company has been investing in. It is, after all, those elements that will help secure the future of the company for the decades ahead.

HEICO is just such a company that draws on a rich history of manufacture, with decades of tradition and experience in the field of fastening and forming technology. The firm began 125 years ago but it would be understating things to say it's moved on significantly, particularly in recent years. A strong investment programme has seen the firm add new machines not only for cold forging, but also in its production site in terms of processes and sustainability. Now, the firm is a very innovative, modern company.

That's a point exemplified at the time of Torque Magazine's visit to HEICO's headquarters in Ense, 40km from Dortmund. During the visit, the manufacturer was working on adding demanding new sector-specific certifications, as well as organising the arrival of a number of significant new advanced machines to expand its capabilities and potential reach into different markets.

Investing to unlock future capabilities

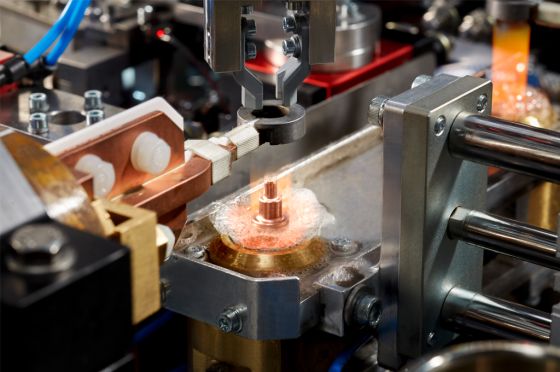

On site, Torque Magazine saw recently installed equipment, with further additions already scheduled. Among them were new packaging lines, cold forging presses and systems for secondary operations.

"In the past few years, we've made major investments in our production technology - from multi-stage presses to semi-hot forging systems - building a genuinely modern manufacturing base," says General Manager Jan Bernd Heimann. "It's important that every visitor leaves with a clear understanding of how we work, and with full confidence in the reliability of our products. Our facilities are state-of-the-art, transparent and can be audited easily - we are moving forward with confidence."

Staying ahead of customer expectations is what drives this approach. "By investing in outstanding technology, we are securing the competitiveness of tomorrow."

Sales Manager Tobias Grobe adds: "We take part in a lot of exhibitions to promote our products on a global scale. We send our goods to 81 countries and have 430 employees globally. We've 120 production machines and 32,000 m2 production area. Every month, we are producing approx. 218 million parts. In addition to our bolt locking and pre-tensioning systems, we can manufacture cold-forged parts ranging from simple rivets or ball studs up to complex, customised parts.

"Besides our core production capabilities, we are able to do annealing, inductive hardening, hardening, self-tempering... all in-house."

Tradition, innovation and R&D

HEICO's achievements have been down, in no small part, to its R&D efforts. Heimann says: "We believe we can only be successful if we have a sizeable investment in R&D and innovative ideas. Otherwise, products could be bought somewhere else easily, right? We need to be flexible and aim to set ourselves apart from other companies. This is very important, so we have concentrated in the last 15 years on these areas, finding fields of applications or products which help us to grow.

"Over the past decades, we have significantly expanded the number of employees dedicated to developing new technical solutions. Innovation is not something you can simply switch on or off - it is a continuous process of becoming more innovative and meeting customer needs and solving their challenges in the fastener industry."

In terms of innovation, the inception of HEICO-LOCK® Wedge Lock Washers, launched in 2010, was a milestone. Designed for maximum reliability even under extremes of vibration or dynamic loads, the Wedge Lock System precipitated entering new sectors and geographical markets.

The HEICO-LOCK® Wedge Locking Systems with their wide range of different bolt locking devices, form a key part of the core business - complementing the two other divisions HEICO-TEC® Tensioning Systems and HEICO-FORM Cold Forging Parts.

State of the art

"Our testing and measuring technology are state of the art," Grobe tells Torque Magazine, revealing that the firm's extensive quality equipment can handle vibration testing up to M64, something few others can reportedly offer.

Heimann picks up the point: "Our quality laboratory is a major focus for us and an area where we have developed ourselves a lot. Customers facing bolting challenges are encouraged to reach out to us. They bring us their application and then we analyse it... and of course, provide tailored solutions using our products."

That in-house capability is backed with a bright network of sales engineers and certified Fastener Engineers (DSV), all bringing technical expertise and hands-on experience to support its customers.

Contrary to other companies, HEICO has always effectively leveraged challenging times to its advantage. “We take advantage of economically difficult periods to refine our products and processes, strategically investing in promising ideas and machinery to drive future success. I believe that every crisis makes us stronger, and I face them with confidence, not fear."

HEICO stayed resolute amid the disruption and uncertainty of Covid, with Jan Bernd Heimann pushing forward its ongoing expansion programme. That bold decision has paid off, positioning the company to confidently embrace the next phase of growth and innovation.

"What's the story with the polar bear?"

The firm has long concentrated on production and sales, but HEICO is increasingly seeing the value of marketing and outreach. It partakes in a huge number of exhibitions, in part for that purpose. And in terms of sticking in someone's mind, HEICO has an additional ace up its sleeve - probably one of the most memorable logos of any firm in the fastener business. "When customers come and visit us, they always ask, what's the story with the polar bear?"

The logo of approximately 100 years ago featured a polar bear stepping on a 'push pin'. The story goes that these were often poor quality and broke when pressure was applied to the head. HEICO solved this problem with a stronger product, using a special riveting process, capable of withstanding strong forces (figuratively illustrated by a polar bear).

Sustainability

HEICO has had its foot on the throttle regarding sustainability for some years now and 30% of its energy needs are met through renewable sources, including Biogas, which is produced just a few kilometres away. Clever building management systems mean HEICO can switch off departments, specific areas and machines whenever required, making energy use supremely efficient. There's a business need to be more sustainable, but the firm is also passionately behind the topic ("Sustainability is a corporate commitment. We can no longer operate as we did in the past").

The firm also has some eye-catching ESG commitments too. You can find animals in the grounds of the business. It taps into the social commitment of this family-owned company. Kindergartens, groups and clubs are among the visitors who make the trip to spend time with and look after the animals, firmly placing HEICO as a resource and hub to benefit and connect locals.

Family values

One of the through lines from HEICO's past to the present is passion. There is no doubt this has something to do with the fact the firm is a fourth-generation family-owned company.

"I think our values are very important. This year, we are celebrating the 125th Jubilee, and 125 years as an industrial company. It's a long story, with some good years and some really exciting years. And to be honest, we are very positive for the future."

Jan Bernd Heimann is the owner as well as General Manager of the HEICO Group. Part of the fourth generation of the founding family, he officially started with the company around 20 years ago. The HEICO management team also includes Head of Sales Tobias Grobe who has 27 years of experience with the company. He says: "As Jan explained, when customers visit us, they should feel the HEICO spirit - a culture of professionalism, passion and innovation - and leave inspired, confident and assured that they are working with a company they can truly trust."

HEICO - Setting the standard in fastener innovation

There have been many milestones for HEICO over the 125 years, with 2015's 'most innovative company' award a recent highlight. A year later saw the firm launch its HEICO-TEC® Tensioning Systems. In 2024, the HEICO-LOCK® Combi-Washers picked up the Best Industry Award, showcasing the increasing expertise of the R&D brains at HEICO. The patented combi-washers feature an inner plastic ring with small tabs, allowing the locking device to be pre-assembled with any bolt type: a clear advantage over standard locking bolts. In addition, the user's hands remain free during assembly, with no need to handle bolt and washer separately.

HEICO's latest innovations are the revolutionary, patented HEICO-LOCK® Reaction Washers, engineered specifically for use with high-torque tools. Successfully launched in autumn last year, these washers enable reaction-arm-free tightening of large bolted joints while effectively protecting bolts against self-loosening. In addition, HEICO offers a special counter- washer to accommodate movement on the passive side of the bolt connection. Beyond the two-washer based HEICO-LOCK® system, the new HEICO-ONE Safety-Washer operates with just a single washer, providing an efficient and reliable solution for a wide range of applications.