FASTENER AND FIXING FOCUS: Nord-Lock’s new X-series washer aims to solve the challenges faced by bolted joints which incorporate polymers and composites. The brand takes us through how the X-series tackles the conundrum…

The use of polymers and sandwich composite materials continues to increase in industrial applications, with impressive strength-to-weight ratio and great corrosion-resistance making them suitable for many different applications. Components made of polymers and composites can be found almost everywhere from cars to wind turbines to airplanes and adhesives are often used when assembling polymers and composites.

Adhesives, however, makes it difficult – if not impossible – to open the joined parts when needed. This is why the industry normally prefers to use bolted joints to allow for facilitated maintenance. Bolted connections are, however, also affected by the new materials introduced in the joint and slackening (due to settlement and relaxation) becomes an increasingly common problem.

Using fibre reinforced plastics in bolted joints

Material used for high strength applications are often fibre reinforced plastics (FRP) and the properties of the FRP varies depending what kind of matrix (base material) is used, what kind of fibers are used, how much fibres (%) are used and the orientation of the fibres. Common fibres are glass, carbon or aramid and they are often oriented in a way to strengthen the material where it is most needed.

Except in 3D composite, fibre directions are perpendicular to hole-axis. This particularity sets the composite properties along the hole-axis equal to matrix properties.

The downside of using an FRP in a bolted connection is the fact that the matrix, or the resin, is made of a polymer.

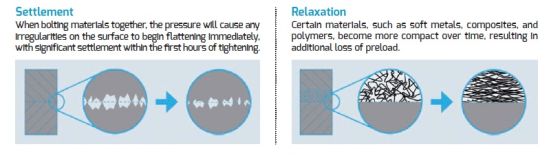

Almost all polymers are viscoelastic which means that their mechanical properties will change over time, resulting in creeping and relaxation. If we compare:

- You have a bolted connection with two metals as clamped parts. The metals will deform elastically under the pressure of the bolted joint as long as the yield point of the base material is not exceeded. When you untighten you will not notice any deformation, it was purely elastic.

- Let’s take a new bolted connection, this time with two parts of polymer material. When exposed to pressure the material will start to creep, even though a relatively low clamp load is applied. The creep phenomenon causes settlements and slackening in a bolted connection which leads to a decrease of the clamp load and finally the parts are no longer clamped together.

As polymer materials are softer than metal materials, so there is an increased risk for slackening which can have catastrophic consequences for the safety and reliability of the bolted connections.

How the Nord-Lock X-series expands design possibilities

How can one solve a design challenge for a bolted joint which incorporates polymers and composites? One solution that has been on the market for some time is to use a metallic insert in the holes. The insert is placed to strengthen the holes and makes the bolted connections purely metallic while the clamped material remains plastic. The joint gains in strength on one hand, but on the other hand the manufacturing costs are high. This solution also modifies the vibration response (resonant frequency) and it is not able to safely secure preload against creeping, relaxation, self-unscrewing.

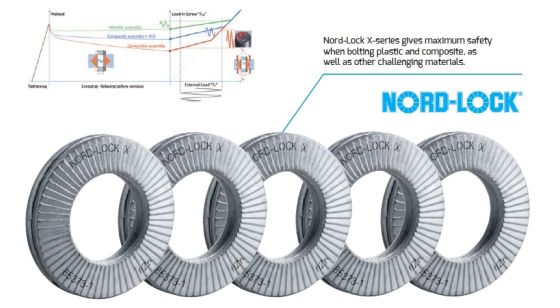

Another solution which is fairly new to the market is the Nord-Lock X-series washer. The conical shape of X-series washers creates an elastic reserve in the bolted joint to compensate for loss of preload due to slackening. The spring effect is combined with wedge-locking technology, securing the bolt with tension against spontaneous bolt loosening. It provides maximum safety for the joint even at a low clamp load. The multifunctional wedge-locking technology has a number of advantages over conventional bolt securing solutions. It ensures total bolt security and is ideal for applications that incorporate challenging materials, designs, and/or conditions.

Evolution of preload during time

The graph shows fatigue stress that increases when assembly is subjected to a similar axial load “Fa”. Metallic assembly: no creeping + good load factor; composite assembly: creeping +bad load factor; composite + X-series: reduced creeping effect + improvement of load factor.

Application example – cranes with elastomeric pads

Elastomer is one type of polymer and is a common material in telescopic equipment. It has a huge advantage in added flexibility to the sliding parts of the boom and a low friction coefficient. The material is also resilient against corrosion.

Recently a crane manufacturer, experiencing serious bolt loosening, contacted a Nord-Lock sales engineer and presented a very typical challenge when bolting composites. Thirty per cent of the joints holding the elastomeric pads inside a telescopic boom on one of their models of mobile cranes were coming loose after a few months of service at the customer’s. The combination of the polymer, a short clamp length and thick paint layers was making settlement and relaxation in the joint inevitable. The large percentage of bolts coming loose caused inoperability of the telescopic booms for the users (customers) and required express maintenance covered by the manufacturer’s warranty. This has led to large expenses for the manufacturer of the cranes and has harmed its brand image.

Introducing Nord-Lock X-series washers on the application solved the loosening issues and eliminated the added cost for repair and warranty. Even though the application also incorporated additional design challenges, including short clamp length and multiple layers (casing, shims, washers and pad), the bolted joints are now safely secured with the X-series washers. Since the implementation, no bolt loosening has been recorded on the booms. The result is a manufacturer who can enjoy the benefits of elastomeric pads whilst still ensuring that his bolted connections are safely secured and his products are safe and reliable for the end-users.

This article was first published in Torque Magazine.