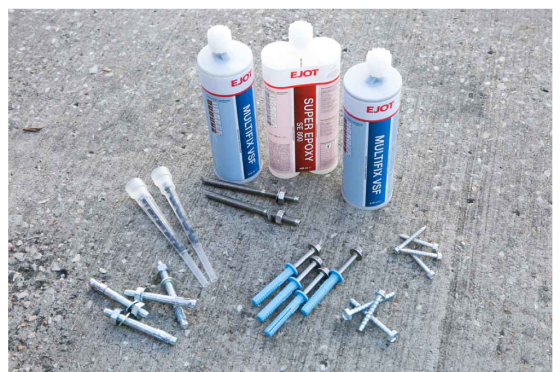

Injectable chemical anchoring systems from EJOT combine high strength with ease of use to provide a dependable anchoring solution for cracked and non-cracked concrete, brick and block in the most demanding applications.

EJOT offers two systems to meet the requirements of a wide variety of applications – Super Epoxy SE 800 and the Multifix VSF. Both work by combining a chemical resin with a threaded stud which, when installed and cured, provides a secure anchoring fix with assured long-term performance in even the most severe environmental conditions.

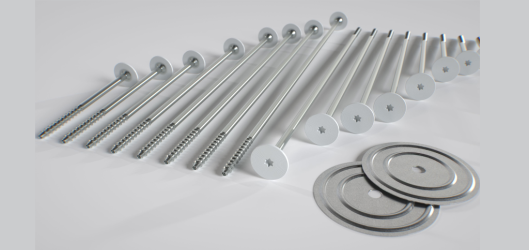

At the core of the systems is a high-quality threaded stud available in zinc plated and A4 stainless steel options. This features an embedment depth marker on the shaft to help set the stud to the correct level, and a hexagonal nut and washer mechanism precision engineered by EJOT for problem-free installation.

Both the EJOT Super Epoxy SE 800 and Multifix VSF can be used in cracked and non-cracked concrete. They are ETA approved for anchoring threaded rod or rebar in concrete, fire rated and have an A+ Rating for VOC content, with a superior design to provide high bond strength with high load, dynamic and chemical resistance.

The EJOT Super Epoxy SE 800 is a very high load epoxy injection mortar for solid base materials, including stone, which can be used in dry, wet and flooded holes. Its performance capabilities make it an extremely versatile solution, suitable for use in warm/hot regions, diamond drilled holes and oversized holes. There is no shrinkage, and it is thixotropic, meaning it can be applied in both vertical and horizontal directions.

EJOT Multifix VSF is a styrene free low-odour anchor mortar. It is a two-component chemical anchoring system based on a ‘high reactivity’ vinylester resin. It is fast-curing, and it can be used underwater as well as in potable water applications, being WRAS approved.

Both systems are suitable for use in critical or overhead applications and enable anchoring close to the edge of concrete and at small anchor spacings. Installation is a simple process with the hole preparation involving a straightforward drilling and cleaning process prior to inserting the adhesive and the threaded rod.

To achieve the correct SE 800 or Multifix VSF design and specification with ease, designers can utilise EJOT’s comprehensive, user-friendly calculation software, EJOT® Chemical Anchor Engineering. This allows volume calculations to be determined to optimise usage, saving time versus long hand calculations and improving accuracy in a wide variety of substrates.

For technical, specification and installation support for anchoring systems, contact EJOT UK on 01977 687040 or email info@ejot.co.uk.