Sunco specialises in high-quality fasteners. Speaking with Torque Magazine, the company shares insights into its history, media strategy, the creation of its mascot, Socket Boy and its future plans. This firsthand information offers a deeper look at Sunco's unique approach and vision for the industry.

Can you give us an overview of Sunco Industries and its core areas of expertise?

Since its founding in 1946, Sunco Industries has been at the forefront of the screw industry, pioneering the use of IT to manage plated product inventory and introduce trivalent plating products. In recent years, we have enhanced our capability to deliver products in small boxes or smaller quantities, including single-piece shipments, to flexibly meet the diverse needs of our customers.

At our logistics centre, we utilise a proprietary mathematical model to operate a logistics system that is both highly automated and labour-saving, setting a new standard in the industry. We are also expanding the business model developed in Japan to overseas markets, building a system that enables fast and secure cross-border deliveries.

Sunco currently works with around 1.300 suppliers and 6,000 customers in Japan, along with 70 customers overseas.

What are the key industries and markets Sunco currently serves in Japan and abroad?

As a primary distributor, we sell mainly through wholesalers and retailers. More than 98% of our business is, and will continue to be, within the Japanese market.

Overseas, we are focusing on addressing minor issues related to JIS screws and replacement parts for cars and motorcycles manufactured in Japan. Although the market is not large, we believe this is the area where we can first leverage our strengths to support customers around the world.

How does Sunco differentiate itself in the competitive Japanese manufacturing and fastener industry?

Our biggest differentiating factor is our product lineup of over two million types, mainly JIS products, with 300,000 of them kept in stock for immediate delivery. While JIS screws are not widely distributed globally, there is demand for them in countries where Japanese manufacturers are active.

In this context, we are increasingly able to address issues faced by local corporations and screw trading companies, such as the inability to obtain JIS screws promptly or insufficient quantities for production. For companies looking to expand their product range, we offer flexible support, including non-JIS standard items.

We also develop and stock products based on customer feedback, and in some cases. these items are already held in general stock by the time of the next inquiry.

Under the slogan "Your special is our standard", we have built this business in Japan and are now expanding it overseas.

What are the company's strategic priorities for the next three to five years?

Our goal is to bring the convenience and quality of Sunco Industries to screw distributors worldwide, and to introduce Made-in-Japan screws to the global market. To achieve this, we will invest in enhancing our logistics capabilities, as well as in systems such as multi-currency payment and English-language standard naming.

In the Japanese market, we will continue to pursue our longstanding product and customer expansion strategy, built on the principle of risk management that does not rely on a single industry or customer. We will further broaden our product lineup by offering items tailored to customer needs.

How has Sunco responded to recent global supply chain challenges?

Due to CBAM (Carbon Border Adjustment Mechanism) and restrictions on Russian materials, an increasing number of companies are finding their existing procurement channels at risk. From the perspective of supply chain stability, we have been highlighting the advantages of Japan in terms of location, quality and delivery management.

Our network of over 1,300 screw-related manufacturers in Japan ensures a stable supply of our core products, which are consistently kept in stock. In addition, the weak yen has enhanced our price competitiveness.

Sunco aims to be the preferred partner in the global supply chain and is committed to building trusted relationships with customers worldwide, guided by our management philosophy of continuously doing work for which our customers can always say thank you.

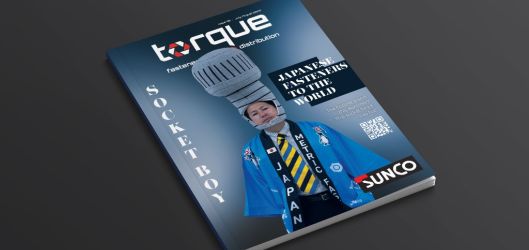

How many copies of Socket Boy Magazine are distributed per issue?

We currently publish 10,000 copies of Socket Boy Magazine, which we distribute free of charge to customers and prospective customers by post and at trade shows around the world. A web version is scheduled to launch around August this year. offering readers worldwide insights into the Japanese screw industry and the history and culture of Higashi-Osaka City, a hub of manufacturing,

The content will cover not only the screw industry but also Japanese manufacturing, history, culture and a variety of other topics. If you are interested, please subscribe using the QR code.

Why did Sunco decide to launch a digital version of Socket Boy Magazine in addition to the print edition?

The print version of Socket Boy Magazine was published in January 2024. The web version will feature more in-depth articles and original content exclusive to the digital edition that could not be included in print. We hope you will enjoy the web version as much as the print edition.

How has Socket Boy Magazine contributed to Sunco's business and brand recognition so far?

We have received inquiries through social media posts related to Socket Boy Magazine, and we believe this has significantly increased our company's visibility. We have received subscription requests via social networking sites, and in some cases, even requests for quotes from people interested in Socket Boy Magazine.

In addition to the magazine, the original character Socket Boy is also gaining attention, and at trade shows we are often approached by people who say, "SUNCO is the company that created Socket Boy, right?"

Can you introduce the magazine's editorial team? What is your process for curating content?

Socket Boy Magazine is currently produced by a team of three and focuses on the Japanese screw Industry, as well as the history and culture of Higashi-Osaka City, home to many screw manufacturers.

Aiming to communicate the appeal of Japan's screw Industry worldwide, the magazine actively covers fastener-related exhibitions and events held in Japan.

Recently, we launched a new section called "NEJIDO," which spotlights the management of our domestic suppliers through interviews about their life journeys and future prospects.

The content is highly readable and offers insights into the experiences of those who have transitioned from other industries to the screw industry, as well as those working hard to strengthen the sector.

It appears that Sunco is active on social media, which is not always common for B2B companies. Tell us about your strategy and what results you are hoping to achieve.

We use social media to increase awareness of our company. Social media is a tool widely used by people of all ages and from many countries, and we believe it is an effective way to share information.

We hope this will be a good opportunity to introduce Sunco as an interesting company in Japan and to spark some interest in what we do.

Through our character Socket Boy, we aim to make the world of screws more familiar to people and to provide information in a fun and engaging way.

What communication channels does Sunco prioritise, such as industry media, social media, and trade shows, and why?

Currently, our primary focus is the production of Socket Boy Magazine. In Japan, there are no magazines specialising in the screw industry, unlike in the UK, the US and Taiwan.

Through Socket Boy Magazine, we hope to raise awareness of the appeal of the Japanese screw industry and of Higashi-Osaka, a city renowned for its manufacturing.

In addition to domestic and international fastener-related exhibitions, the magazine was distributed at Smart Manufacturing Week in the UK in June 2024. We also distributed it at the J-Town Cruise event in the US, running from late July to November 2024.

Is there anything else you would like to add?

We will be offering free international shipping again this year for the three-month period from September to November. All International orders placed during this time will be eligible, so please take advantage of this opportunity.

In addition, our "BARA Service" allows you to order from a single screw, making it easy to use even for small quantities. Furthermore, customers who order from our online catalogue, 3QNET, during this period will receive a small but delightful gift.

Don't miss out on this special offer!