As the speed of technology and trends in consumer behaviour accelerates, companies around the world are evolving quickly and TR Fastenings is no exception. TR’s latest product launch of Compression Limiters has been developed to meet the growing global demand from multi-sector manufacturers developing products using plastics, particularly in the EV space.

Compression Limiters reduce the stress that’s generated by traditional threaded fasteners. Demand has mainly been driven by the automotive sector, and applications in the energy and general industrial sectors where high load bearing plastic components are used and have also contributed to the surge in worldwide demand.

Growth in automotive component demand

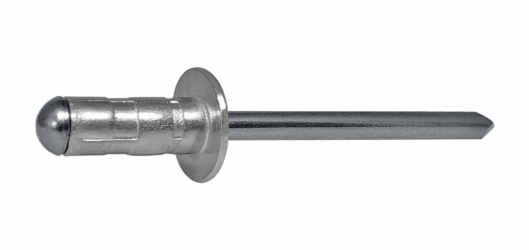

Compression Limiters are used extensively in composites and plastic mouldings as through holes help reduce the stress generated by conventional fasteners. These non-threaded inserts are commonly used in applications where a compressive load is applied to a plastic assembly to prevent the integrity of the plastic being compromised.

These products are used extensively in electric vehicles and the battery housings. As technological advances continue, so does the need to continually develop the primary components that make up an electric vehicle. Newly created giga factories and battery housings manufacturers in Europe, Asia and North America will be looking to include these products in many upcoming automotive research and development projects and with a global presence, TR Fastenings is ideally positioned to meet this demand, whilst also providing technical and design assistance.

The product range

TR’s experience over the last few years is that many of these are designed in specials and required in high volume. There are a number of different types and as a guide the TR’s Compression Limiter range consists of symmetrical, flanged, split seam and oval manufactured from steel, stainless, brass and aluminium.

Net-zero

As we head towards 2030 and net-zero, there will be greater technical requirements from the automotive industry as it continues to boom. The need for joint strength and integrity will remain a critical requirement as manufacturers work flat out to launch new zero-emission electric vehicle models.

Although the fundamental technologies behind electric vehicles have been around for years, it’s only recently that these have come together to produce the EV’s that are now available. As changes in mobility are changing the industry at pace, component manufactures such as TR are leading the way in the design, development and supply of fasteners for plastic.