Sunco Industries has commenced operations at a new warehouse facility designed to significantly enhance logistics efficiency through the introduction of advanced rotary rack systems.

Measuring approximately 75 metres wide, 20 metres high and 30 metres long, the facility offers a storage capacity of around 13,000 pallets and a handling capability of approximately 500 pallets per hour. It also includes specialised pallet slots for long items, with 40 slots for two-metre products and 100 slots for one-metre items.

A central feature of the new warehouse is its rotary rack system, which is equipped with image recognition technology to enable fully automated banding. Using cameras, the system detects whether cardboard cases are missing plastic bands and applies them automatically where required. Goods are temporarily stored within the rotary racks and automatically retrieved in line with each carrier’s scheduled collection times, streamlining the handover process and preventing congestion within the warehouse.

This approach reduces waiting times for delivery companies and represents a significant improvement compared with the previous system, where goods awaiting collection were placed directly on the warehouse floor, limiting operational efficiency.

Initially, the warehouse will work with four delivery companies, with plans to expand coverage following further testing. Once fully operational, the system is expected to further improve both collection and transportation efficiency.

The new warehouse also delivers notable improvements in inbound logistics. Previously, products that had already been ordered by customers at the time of arrival had to be temporarily stored on the warehouse floor, separately from regular stock items. Under the new outbound system, all incoming goods are now stored immediately within the automated warehouse, with only ordered items retrieved later for dispatch. This change streamlines the receiving process, eliminates the need for temporary floor storage and contributes to a reduction in overall floor stock levels.

The facility began receiving goods on 14 October, marking a key milestone in Sunco Industries’ logistics strategy. By removing manual bottlenecks and shortening waiting times for carriers, the new warehouse delivers efficiency gains across both inbound and outbound operations.

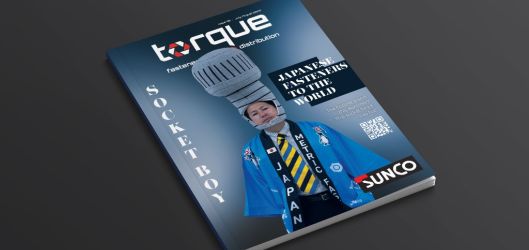

An opening ceremony was held to mark the launch of the facility, during which traditional Japanese rituals were conducted by an invited Shinto priest.